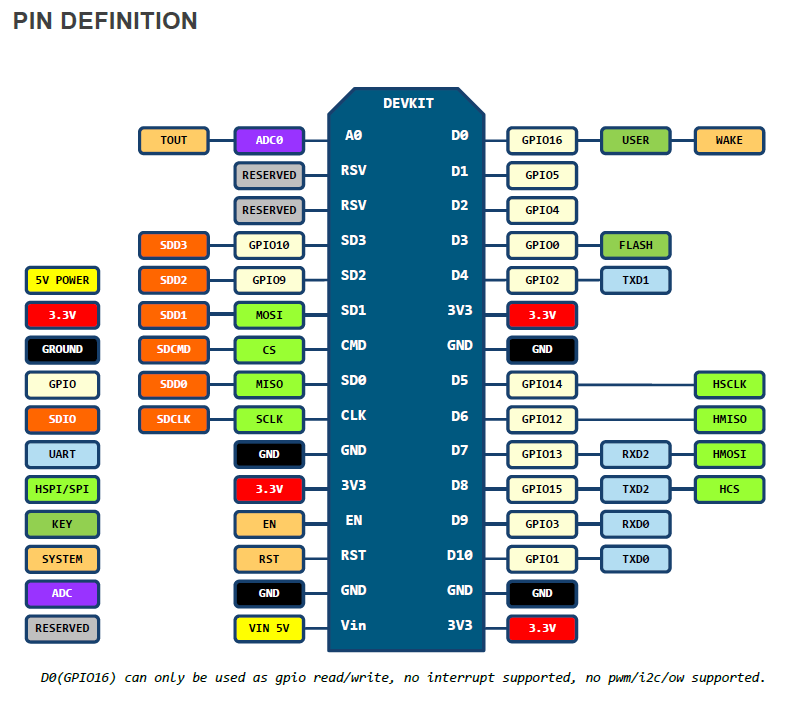

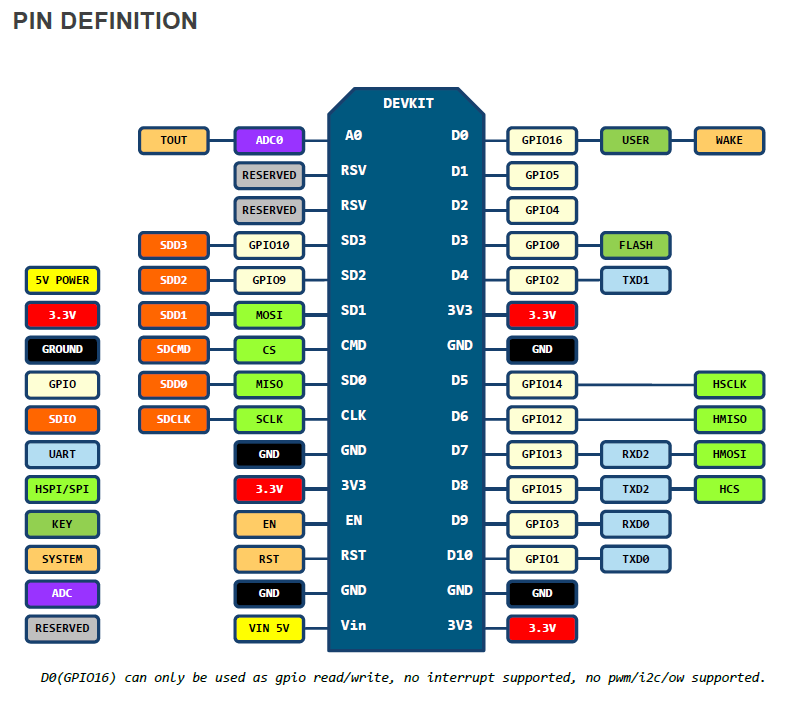

I'm adding the pin layout image I'm using as reference for support

thanks in advance for any help you could provide

Explore... Chat... Share...

Moderator: igrr

/// notes

/// the esp12e USES qio FOR THE PROGRAM FLASH

/// the places GOPI10 and GPIO9 as unavailable

/// unless the flash inside the can is removed and pins 3 and 7 lifted

/// pin 3 is wired to 7 and then to 3.3v

/// pads 3 and 7 are connected to GPIO9 and GPIO10

/// since GPIO9 and GPIO10 are now free and then set the FLASH to DIO mode

//// QIO will now not work

/// DIO mode maybe is the default for the arduino IDE NodeMCU v1 12E board

/// +--------+

/// _CS |1 8| 3.3v

/// DO |2 7| _HOLD

/// _WP |3 6| CLK

/// GND |4 5| DI

/// +--------+

#include <Arduino.h>

const int led = 2;

const int SD2 = 9;

const int SD3 = 10;

void setup()

{

//gpio_init();

Serial.begin(112500);

pinMode(SD2,FUNCTION_3); ////GPIO on 9 and 10 is function3

pinMode(SD3,FUNCTION_3); ////GPIO on 9 and 10 is function3

pinMode(led, OUTPUT);

pinMode(SD2, OUTPUT);

pinMode(SD3, OUTPUT);

delay(1000);

Serial.print("chipid");

Serial.println(ESP.getFlashChipId());

Serial.print("chipsize");

Serial.println(ESP.getFlashChipSize());

}

void loop() {

// put your main code here, to run repeatedly:

digitalWrite(led, 1);

digitalWrite(SD2, 1);

digitalWrite(SD3, 1);

delay(500);

digitalWrite(led, 0);

digitalWrite(SD2, 0);

digitalWrite(SD3, 0);

delay(500);

}

It takes about 20-25 seconds for home assistant c[…]

I tried to upgrade tof my sonoff basic R2 with the[…]

a problem Perhaps you want to define "Probl[…]

Rebooting your router will not give you a faster I[…]

There are no other notifications from esptool.py i[…]

Using the Arduino IDE, you'll learn how to set up […]

In this project, you will post to Twitter using an[…]

In this project, we will build a water level contr[…]

I guess I'm late, but I had the same problem and f[…]

Last night I received my first D1 Minis for a lear[…]

Although I am aware that this is an old post, I fe[…]